Track my order

RESOURCES

The Ultimate Guide to Refrigerated (Reefer) Shipping Containers

Ever wonder how grocery stores keep up with the demand for fresh produce all year round? A big part of the answer lies in the logistics industry, where refrigerated shipping containers play a crucial role. These containers make it possible to transport perishable goods across long distances, helping keep everything from fresh produce to medical supplies in optimal condition. In this guide, we’ll break down what reefer containers are, what makes them essential, and how they’re used in the supply chain. Plus, we'll share practical tips from our experience at Boxhub, where we provide thousands of containers monthly. Let us help you keep your supply chain moving smoothly and your products fresh for your customers.

What are Refrigerated (Reefer) Containers?

Refrigerated containers, or “reefers,” are climate-controlled shipping containers designed to transport temperature-sensitive goods worldwide. The first version of a “reefer” was developed back in 1925 to transport ice cream—meaning they even predate modern, standardized shipping containers. Today’s reefers have come a long way, and are able to maintain inside temperatures from a frigid -85°F (-65°C) to a toasty 104°F (40°C). This precise climate control helps businesses keep various products—from fresh produce and meats to pharmaceuticals and certain chemicals—in prime condition.

Consider trying to ship fresh salmon from Alaska to Florida without refrigeration. It would quickly turn into an unmanageable (and smelly) problem! Reefer containers solve this by enabling safe, efficient transport of perishable items over long distances.

Here are some of the top benefits of transporting and storing goods with reefer containers:

1. Product Quality: Goods can be kept fresh and safe throughout their journey, no matter how far they have to travel.

2. Regulatory Compliance: Lots of products have strict, mandatory transportation rules that require the controlled environment a reefer provides.

3. Waste Reduction: By stopping spoilage in its tracks, reefers seriously cut down on waste, saving both money and resources.

4. Market Expansion: Producers can reach new markets, and consumers can enjoy a wider selection of products all year round.

Already know what you're looking for? Check out our reefer containers on sale or get in touch with an expert on our team.

How Do Refrigerated (Reefer) Containers Work?

Reefer containers have a built-in refrigeration system connected to a power source on shipping vessels or trucks. Different power supply options meet varying needs, with voltage requirements and costs that are important to consider:

Three-Phase (3-Phase) Reefers

• Voltage: Typically requires 440V to 460V, common in the U.S. and globally.

• Use Case: Ideal for large-scale operations with reliable three-phase power access, such as major ports or distribution centers.

• Cost Consideration: Three-phase reefers have higher running costs compared to single-phase reefers but lower purchase price, making them a preferred choice for long-term, high-frequency use.

Single-Phase Reefers

• Voltage: Generally operates on 208V to 230V, modified from standard three-phase reefers.

• Use Case: Suited for smaller operations or locations without three-phase power, such as remote sites or specialized retail applications.

• Cost Consideration: Single-phase reefers are often modified versions of three-phase units, which raises their initial purchase cost, but they can be more economical for lower-frequency use where three-phase power isn't available.Genset-Equipped Reefers

• Voltage: Can provide backup power across different voltage requirements, depending on setup.

• Use Case: Best for transporting extremely temperature-sensitive goods over long distances or during unpredictable travel conditions.

• Cost Consideration: Higher upfront cost due to the additional genset, but the backup power ensures temperature control during power interruptions.

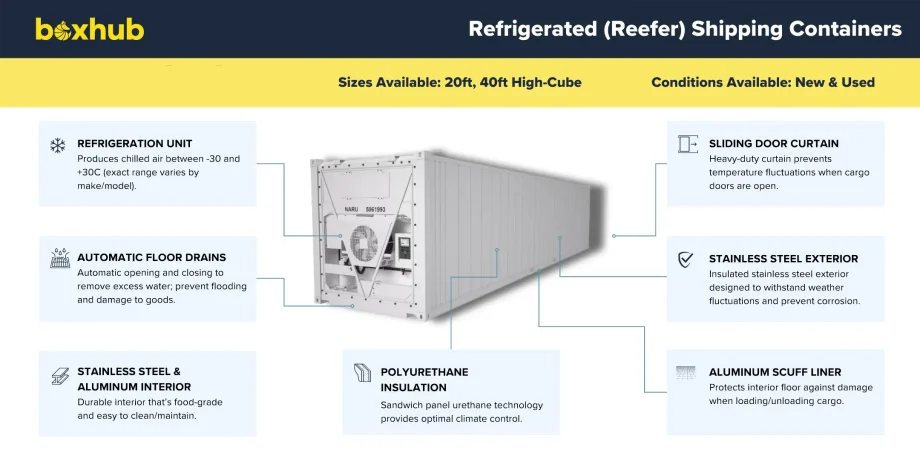

There are five components in a reefer’s refrigeration mechanism that allow it to maintain temperatures to suit its load.

Airflow System

Reefers use a cold airflow design called the T-shaped decking system. Cold air gets pumped from the bottom of the container and moves upwards through the grooves present on the floor. This allows equal cooling across the entire length and breadth of the cargo, leaving no room for any hot spot that could spoil your products.

Temperature Maintenance

Despite popular belief, reefers don’t actually cool your products. Instead, they maintain the temperature of the products at loading, whether cool or hot. Simply put, if you load warm products into a reefer set to a colder temperature, it's not going to cool them down very well.

Picture this: you load ice cream at 40°F into a reefer set to 20°F. Chances are, that ice cream's going to stay at 40°F, and you're risking some serious melty mess. The golden rule? Always pre-cool your products to the temperature you want before loading them up.

Humidity Control

Different cargos require different humidity levels, so reefers are equipped with a dehumidification feature to maintain optimal humidity for each type of cargo. While standard relative humidity in reefers is between 60%-85%, some units can reach as low as 50%. This lower humidity is essential for certain goods like chocolate, which requires a humidity level of around 50% to prevent condensation, mold, and spoilage during transport.

Ventilation

Ventilation is essential for transporting goods like fresh fruits and vegetables, which emit gasses like ethylene that can accelerate ripening. Reefer containers are equipped with adjustable ventilation systems that allow fresh air to circulate inside the container. These systems use air exchange vents to release ethylene and other gasses while simultaneously pulling in fresh air. The ventilation rate can be adjusted based on cargo needs, typically ranging from 0 to 260 cubic meters per hour, ensuring that produce stays fresh and ripens more slowly during transit.

Drainage

Reefers feature a sophisticated draining system, which prevents excess water accumulation inside the container. The system removes excess water while preventing external water or insects from getting inside the container. This keeps the cargo safe and intact.

What are Refrigerated (Reefer) Containers Used For? 4 Most Common Applications

Food & Beverage Industry

Meat and Seafood Industry: From high-end steakhouses to seafood distributors, businesses rely on reefers to keep products like steaks, chicken, and fresh seafood safe for consumption. By maintaining precise temperatures, reefers prevent bacterial growth, ensuring products arrive at restaurants and food terminals in top condition, ready for culinary excellence.

Dairy Industry: Dairy producers, suppliers, and grocery chains depend on reefers to transport milk, cheese, yogurt, and other dairy products from farms to store shelves. The cold storage keeps these goods fresh, preventing spoilage and extending shelf life, so customers always receive quality dairy products.

Beverage Industry: Breweries, wineries, and juice manufacturers trust reefers to preserve the flavor and integrity of their beverages during cross-country shipments. Whether shipping prized vintages from a Napa Valley winery or craft beer from a local brewery, refrigerated containers help businesses ensure that customers enjoy each drink just as intended.

Pharmaceuticals

Refrigerated containers are used to ship medicines and vaccines that require extreme precision in temperature control. In these instances, a few degrees of difference can be a matter of life and death.

Medicines and Vaccines: Many medications, such as insulin, need to be kept between 35°F and 46°F (2°C and 8°C) to remain effective. Reefers ensure these life-saving products maintain their stability and potency right up until they reach the patient.

Biotech Products: Biotech products include sensitive items like gene therapies, cell cultures, and lab-grown proteins, all of which require ultra-cold storage to preserve their molecular structure. These products are often used in advanced medical treatments and research, and any temperature variation could compromise their effectiveness. Reefers provide the precise, low temperatures needed to safely transport these delicate materials across long distances.

Floral Industry

Floral businesses, from large-scale flower distributors to specialized florists, rely on reefers to maintain optimal humidity and temperature levels for their products. By using refrigerated containers, these businesses ensure that flowers stay fresh and vibrant during transport, allowing them to meet the demands of weddings, events, and retail shops across various locations.

Chemical & Petrochemical

Certain chemicals and petrochemical products require a stable temperature and controlled environment to maintain their properties. Temperature-sensitive items like adhesives, resins, or specific compounds can lose their binding effectiveness if exposed to excessive heat or cold. For example, some chemicals must stay at a constant 68°F (20°C) to prevent instability or even a meltdown during transit.

Understanding Refrigerated (Reefer) Container Sizes & Dimensions

When it comes to reefers, size really does matter! Reefers are more expensive for shipping/storing goods than a standard shipping container, so you don't want to pay for empty space, and you definitely don't want to cram too much sensitive cargo into a small space. Standard-size reefers come in three sizes - 20ft, 40ft, and 40ft high-cube (HC). Let’s take a closer look at each of them.

20ft Reefer Containers

20ft reefers are ideal for shipping smaller loads of perishables or heavy items as 20fts have a heavier weight limit vs. 40ft containers.

Measurement

20ft Reefer Container

Internal length

17.9 ft / 5.44 m

Internal width

7.5 ft / 2.29 m

Internal height

7.5 ft / 2.27 m

Tare weight

3,080 kg / 6,790 lbs

Payload capacity

27,400 kg / 60,417 lbs

Cubic capacity

999 ft³ / 28.3 m³

40ft Reefer Containers

Choose 40ft reefers if you have bigger shipments that need more room to breathe.

Measurement

40ft Reefer Container

Internal length

37.9 ft / 11.56 m

Internal width

7.5 ft / 2.28 m

Internal height

7.4 ft / 2.25 m

Tare weight

4,800 kg / 10,584 lbs

Payload capacity

27,700 kg / 61,079 lbs

Cubic capacity

2,093.3 ft³ / 59.3 m³

40ft High Cube (HC) Reefer Containers

With an extra foot of headroom, 40ft high-cube refrigerated containers are your go-to reefer if you have bulky cargo that needs extra vertical space. If you’re shipping assembled furniture that needs to stay cool, this reefer is the one for you!

Measurement

40ft High Cube (HC) Reefer Container

Internal length

38.0 ft / 11.58 m

Internal width

7.5 ft / 2.29 m

Internal height

7.9 ft / 2.40 m

Tare weight

4,480 kg / 9,880 lbs

Payload capacity

29,520 kg / 65,080 lbs

Cubic capacity

2,380 cu ft / 67.3 m³

Weight Considerations

Tare Weight: That's how much the empty container weighs (it varies depending on the size).

Maximum Payload Capacity: The most weight you can safely place into the container without breaking it (or the law).

Overloading Risks: Packing too much in a reefer can jeopardize the cooling and damage the refrigeration unit. Not to mention, it's a safety hazard. Better to play it safe than sorry!

Looking to buy a specialty container? Boxhub is the place for you. We are the nation’s number one online marketplace for buying containers, with personalized buying support at every turn and delivery within 5-7 business days.

Types of Refrigerated (Reefer) Containers: Which is the Right One for You?

Aside from size and voltage, you should also consider if the container's features match your cargo’s needs. Let's take a look at the main types of reefer on the market today.

Closed Reefer

As one of the most widely used types, the closed reefer features a built-in refrigeration unit, making it ideal for businesses needing consistent, reliable temperature control for perishable goods. Whether you’re a grocery supplier, restaurant distributor, or specialty food retailer, this type of container is a dependable choice for transporting items that require strict temperature regulation.

Modified/Controlled Atmosphere (MA/CA) Containers

These containers manage oxygen and carbon dioxide levels to slow down the ripening process, ideal for transporting fresh fruits and vegetables sensitive to atmospheric changes. The sender typically presets the ideal gas levels based on the cargo’s requirements, and the container’s technology maintains these levels throughout transit. This controlled environment is particularly useful for products like avocados, ensuring they stay fresh from Mexico to U.S. supermarkets, without ripening too quickly.

Automatic Fresh Air Management (AFAM) Containers

These specialized reefers automatically regulate the intake of fresh air based on the cargo’s specific needs. Using sensors, AFAM containers measure the levels of gasses emitted by goods, such as carbon dioxide (CO₂) and ethylene, which are common in perishable items like fresh produce and flowers. By adjusting fresh air intake accordingly, these containers maintain optimal conditions to prevent spoilage and preserve freshness. For example, when shipping fresh-cut roses from Colombia to New York, AFAM containers help keep them vibrant by balancing air quality, so they arrive fresh for that special someone.

Ultra-Low Temperature (ULT) Containers

This type of reefer can maintain temperatures as low as -94°F (-70°C). ULT containers are the ice-boxes for specialized goods like certain pharmaceuticals, biotech products, and chemicals. Real-world example: Transporting vaccines that need ultra-cold storage. (We're talking cooler than a polar bear's toenails here!)

Cost Analysis: Renting vs. Buying Refrigerated (Reefer) Containers

As with standard containers, you can either rent or buy a reefer. It all depends on your business needs with each option having its pros and cons.

Renting Reefer Containers

Advantages:

• More Flexibility: Renting a container gives you the flexibility to choose the size and type of container depending on your current need. And when you are done using it, you can return the container without having to worry about reselling it.

• Lower Upfront Costs: Renting reefers could be a good deal if you have short-term shipping requirements or you’re working on a bootstrapped budget. Lower upfront costs save you from burning cash.

• Maintenance: Rental companies often take care of maintenance and repairs of the containers. So, that's one less headache for you, both in terms of money and time!

Disadvantages:

• Higher Long-Term Costs: If you keep renting for a long time, say for several months, then it can end up costing you more than buying.

• Dependency on Rental Companies: Every time you want to ship cargo, you have to rely on a rental company and the availability of their reefer containers. Plus, you’ll also have to depend on these companies for the container’s maintenance and service. It’s a risk!

• Limited Customization: You can’t outfit your container with modifications (like man-doors)if you’re renting it.

Buying Reefer Containers

For businesses that always need temperature-controlled shipping, buying a reefer (or several) can save you money in the long run. For instance, a pharmaceutical company that's always shipping temperature-sensitive products might find that buying reefers is a smart investment, giving them better control and saving money over time.

Advantages:

• Long-Term Savings: Look at it like an investment. Once you own a reefer, you don’t have to pay monthly rental fees anymore, saving you money in the long run.

• Freedom of Customization: You can kit out a purchased reefer to fit exactly what you need—be it an extra insulator, shelves or, even extra doors.

• Asset Ownership: When you buy a reefer container, it becomes part of your business assets, which can be a financial plus. And if you no longer need it, you can sell it and take advantage of their strong resale value (there's even a strong market for non-working reefers, thanks to their insulated properties)

• Additionally, you have complete control over its maintenance and repairs, ensuring that the reefer stays in good condition and you know exactly what’s traveled in it.

Disadvantages:

• High Initial Investment: Buying a refrigerated container requires an upfront investment that may be difficult for small businesses with a limited budget.

• Maintenance Responsibility: Though you have complete control, you will also have the added responsibility of maintenance and upkeep of the reefer.

• Limited Flexibility: Once you’ve purchased a reefer, it’s yours to keep, which means you’ll need to allocate storage space for it. While owning a container is an asset, it can become challenging if your business needs change and you find yourself needing a different type or size of reefer - or simply more room to store it.

Ready to buy a reefer container? Browse our inventory or consult with one of our specialists today.

Best Practices for Loading & Unloading Refrigerated (Reefer) Containers

A friendly reminder here—reefers maintain a temperature based on the cargo’s need, be it cool or warm. It does not cool your products! This makes it highly important to understand the loading and unloading process to keep your temperature-sensitive goods in tip-top shape.

Pre-Cooling

Always prep the reefer container and the cargo before loading to make sure your cargo travels at the desired temperature. Example: If you're a dairy company shipping milk that needs to stay at 39°F (4°C), you’ll have to cool down both the container and the milk to this temperature before loading. Otherwise, pallets upon pallets of precious cargo could spoil.

Proper Stacking and Airflow

Good airflow is essential for maintaining an even temperature throughout the container, so ensure that no air vents are blocked by cargo. Placing products on pallets allows air to circulate underneath, which is especially important for frozen items like fish filets. Avoid overloading the container, as cramming in too much can reduce the efficiency of the refrigeration unit, potentially leading to spoilage. Sometimes, less really is more!

Quick Loading and Unloading

Remember, every second counts when you're dealing with temperature-sensitive cargo,so swift movement is the key. Try to keep the container doors open for as little time as possible to avoid temperature swings.

If possible, use a loading dock with air curtains. These cool devices help maintain the inside temperature by creating an invisible barrier to block outside air and humidity from entering the container, even when the doors are wide open.

Maintenance & Care: Making Your Reefer Container Last

Just like standard shipping containers, reefer containers weather rough ocean journeys. So, regular maintenance is vital for reefer containers to work efficiently and avoid costly breakdowns.

Reefer containers may require repair and preventative measures for five common types of damages: physical damage during loading and unloading; infestation by rodents, insects, and pests; contamination due to spillage of chemicals; component or equipment failure; and damage by harsh environmental conditions in different climatic zones.

Routine Maintenance

Set up a regular service schedule based on what the manufacturer recommends. This should include regular check-ups on important parts like compressors, fans, and refrigerant levels.

Assume your logistics company specializes in moving pharmaceuticals. In order to ensure your reefer units are working perfectly, you'd probably want to do thorough maintenance checks at least every three months. This will help minimize the risk of any temperature hiccups that could ruin a whole shipment of medicine.

Cleaning

Give the inside a good scrub-down after each use. This will help get rid of unfavorable smells left behind by fresh produce, especially if it’s seafood. Thorough cleaning will also prevent cross-contamination between different shipments. A clean reefer is a happy reefer!

Seal Leaks and Cracks

Overuse or rough handling can lead to damage in the refrigeration system, which may decrease the efficiency of the entire unit. Regular inspections are essential to detect and seal any leakages promptly. While the only way rodents can enter is through damage or when the doors are open, sealing potential entry points can further ensure the safety and integrity of the cargo.

Monitoring and Record Keeping

Keep detailed records of all your maintenance work and temperature readings during transport. This helps you spot potential issues early on and is important for staying compliant with regulations. (Plus, it'll keep you in the good books with inspectors!)

Refrigerated (Reefer) Container Regulations & Compliance

Staying on the right side of the law is crucial for all— you, your logistics company, and your cargo. Nobody wants to play hide and seek with rules at the cost of delay in shipping! So, let’s go through the mandatory checks:

International Standards

• ISO Standards: ISO (International Organization for Standardization) standards are benchmark guidelines set out to ensure safety and efficiency of reefer containers. If you’re using your reefers for shipping, you must make sure they meet ISO regulations.

• CSC Certification: All shipping containers, refrigerated or otherwise, require a Convention for Safe Containers (CSC) certification to confirm they meet all the necessary safety standards for transportation.

Food Safety Regulations

• FDA's Food Safety Modernization Act (FSMA): In the US, you must abide by FSMA’s guidelines for safe transport of temperature-controlled food products.

• HACCP Guidelines: The Hazard Analysis and Critical Control Points guidelines have laid out extensive guidelines to ensure that all critical points are monitored and tracked during the transportation process. So, if you're a food distributor, you'd follow HACCP guidelines and maintain the records too.

Pharmaceutical Guidelines

GDP Compliance: Storing and transporting medicines and vaccines require a specific controlled environment. Good Distribution Practice (GDP) standards ensure that suitable conditions are maintained throughout the journey to maintain their vitality. In a real-life scenario, a vaccine manufacturer complies with GDP by using reefers with real-time temperature monitoring and backup power systems.

Environmental Regulations

• Emission Standards: Emission standards encourage the use of energy-efficient reefer units, reducing greenhouse gas emissions and the overall carbon footprint of the supply chain. By investing in units that meet or exceed these standards, companies contribute to a cleaner environment while also benefiting from reduced energy costs. Each step, from choosing low-emission units to regularly maintaining equipment, plays a part in reaching global sustainability goals.

The Future of Reefer Containers in Logistics

With technology and sustainability waving the magic wand, the future of reefer containers is indeed bright—and cold!

Technological Innovations

• IoT Integration: With IoT (Internet of Things) devices, managing reefer containers has never been more seamless. Real-time data is now at logistics professionals’ fingertips, allowing them to remotely monitor and adjust temperature and humidity settings to meet specific cargo needs. Plus, they can track the container’s exact location, ensuring cargo integrity every step of the way.

• Blockchain Technology: Blockchain enhances transparency and traceability across the reefer supply chain. Customers can access accurate, up-to-date information on their shipment’s status and location, adding a layer of security and confidence that their goods are well-protected from origin to destination.

- • Artificial Intelligence (AI): AI is a powerful ally in reefer logistics, analyzing data from IoT sensors to predict and address potential issues before they escalate. AI can also optimize routes and make proactive temperature adjustments based on the cargo’s requirements, almost like having an extra set of hands dedicated to safeguarding the cargo’s quality.

Just imagine the efficiency and credibility of a shipping company that uses IoT sensors to monitor conditions and blockchain to provide customers with transparent tracking. Talk about high-tech!

Technological Innovations

• Eco-Friendly Refrigerants: With growing environmental concerns, logistics companies are making a strategic shift toward eco-friendly refrigerants. Unlike traditional refrigerants, which contribute to greenhouse gas emissions, these environmentally safer alternatives minimize harmful impacts and reduce the overall carbon footprint of reefer containers. While standard reefers still rely on conventional refrigerants, the adoption of eco-friendly options is on the rise, helping customers expand their business footprint with a lighter environmental impact.

• Energy Efficiency: Turning to nature for a power source is a real game changer. Recent developments of solar-powered reefer units and improved insulation systems will lower energy consumption to a great extent.

The good news is that some logistics companies are already using reefer containers with solar panels, reducing reliance on traditional power sources and contributing to sustainability goals. Mother Earth approves!

Reefer containers aren’t just boxes to keep things cold—they’re essential players in the global supply chain. At Boxhub, we’re here to help you make the most of them. With the right knowledge, these containers can support your commitment to high-quality service and reliable deliveries, while also keeping your cargo safe and fresh.

As consumers expect more fresh and safe products delivered right to their doors, understanding the best practices for reefer containers—like maintenance, compliance, and tech upgrades—can help boost your company’s reputation and reliability.

Thinking of upgrading your refrigerated storage? Boxhub has helped thousands of businesses make smart choices about specialty containers. Whatever your needs, we’re here to make your logistics journey as “chilled” as possible!

About Hannah Swinkin

Hannah is a B2B marketing leader with a passion for container upcycling projects and cargotecture. She sharpened her marketing expertise at disruptive tech companies transforming antiquated industries, including shipping, parking, and commercial real estate.

Continue Shopping

Loading cart